Minimal in form, weight and waste, our single-material structures elevate space with their sculptural, illuminating presence.

LightMass^ represents a new approach to illuminating space. In this age of high-quality LED lighting technology, shades are no longer required to diffuse light. So what next for the light shade? It still has a furnishing function, softening and defining space, but is now freed from conventional forms, and from direct integration with the light source. It has given us the artistic freedom to conceive LightMass^ as sculptural lighting structures that interact with the LED beam in their own way; capturing it, shaping it, recasting it. We call it the lantern effect.

lighting structures that interact with the LED beam

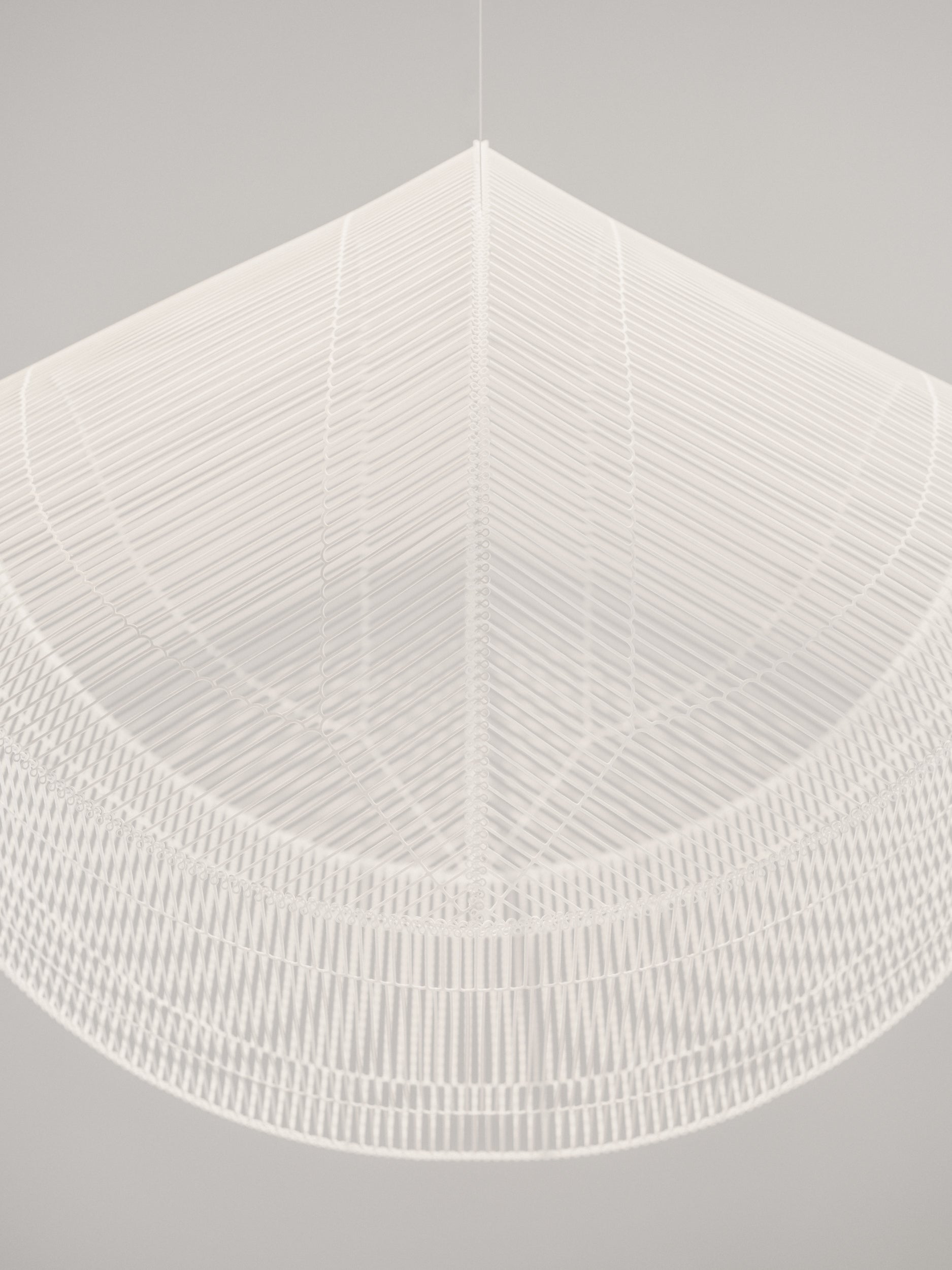

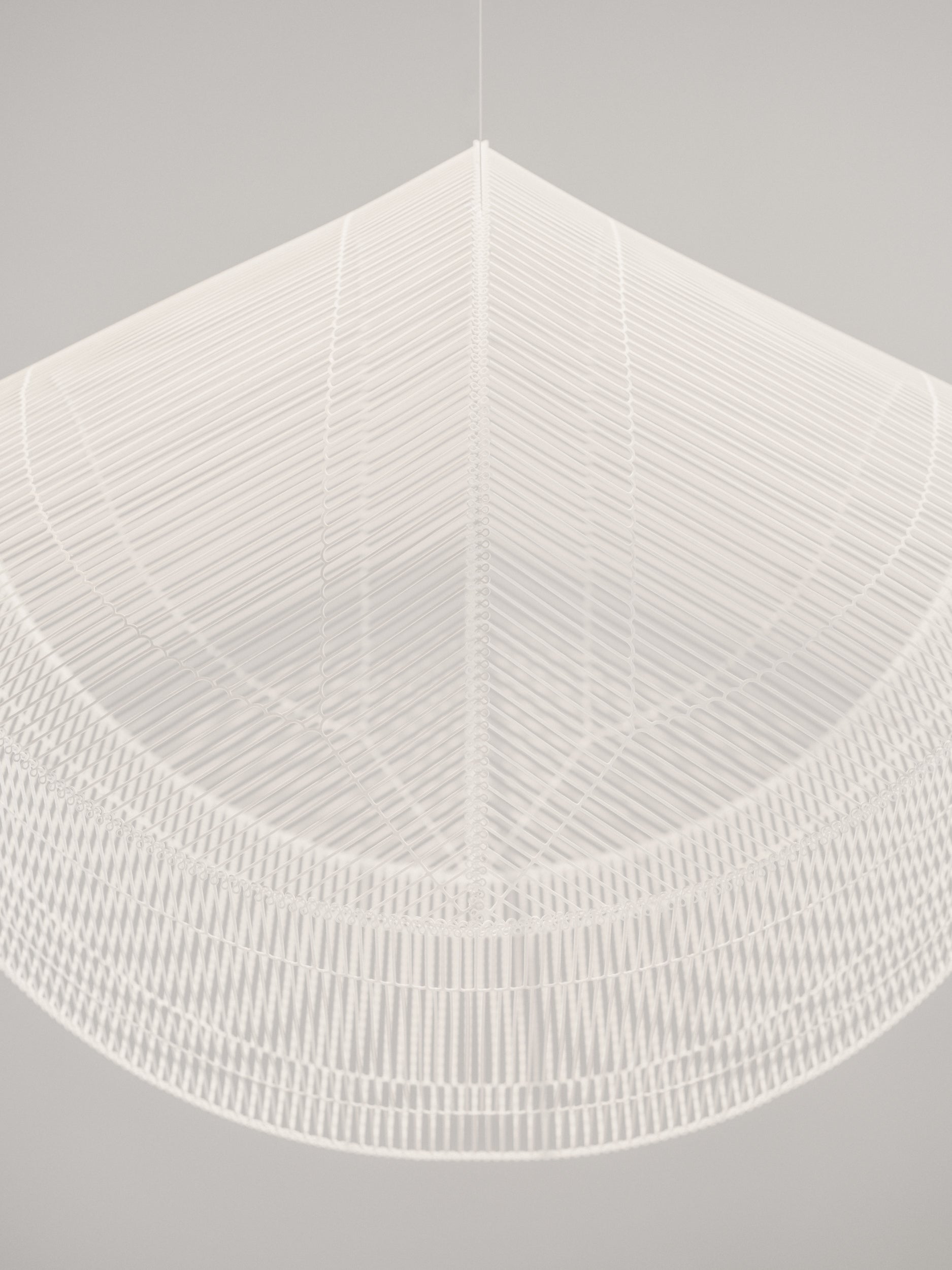

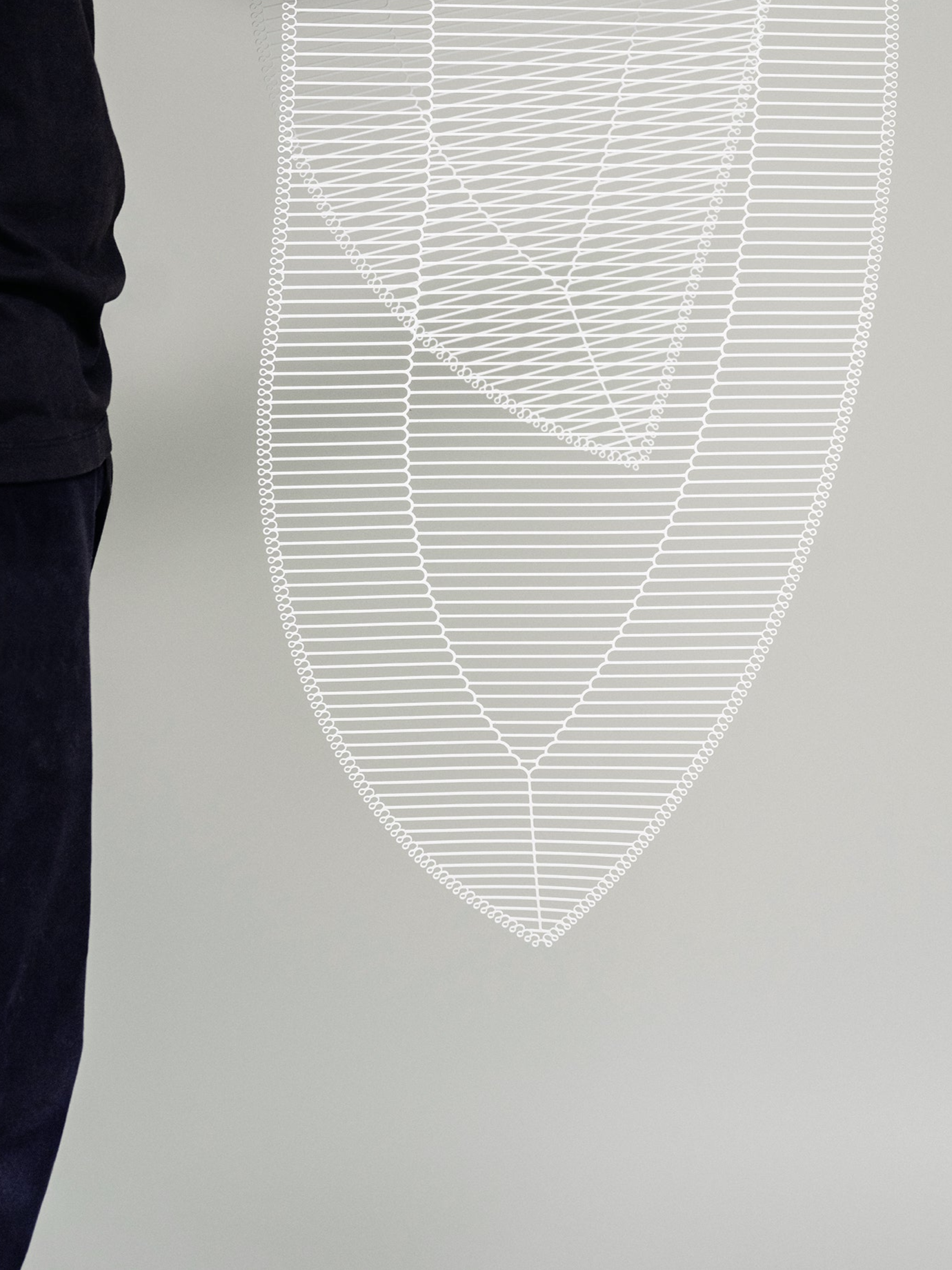

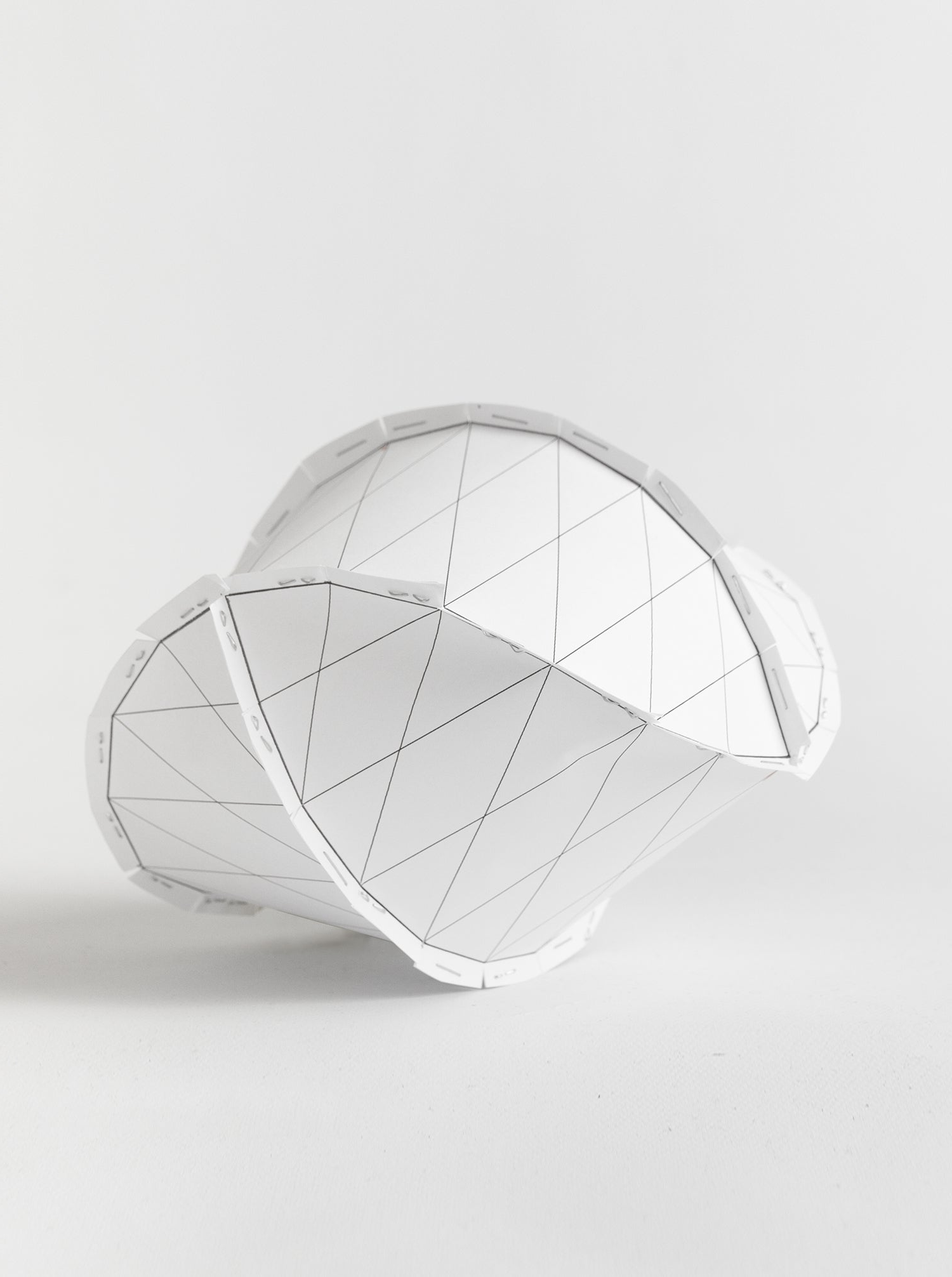

LightMass^ is our response to the new freedom in lighting design. Moving into the realm of sculpture, the essential, translucent volumes of the LightMass^ collection float in space, enclosing it, defining it, but not blocking it. When switched off they hover like airborne line drawings. When switched on, the translucent mesh surface intercepts the light and reflects it, giving structure to the luminescence, while the sculptural forms furnish the space.

sculptural forms furnish the space

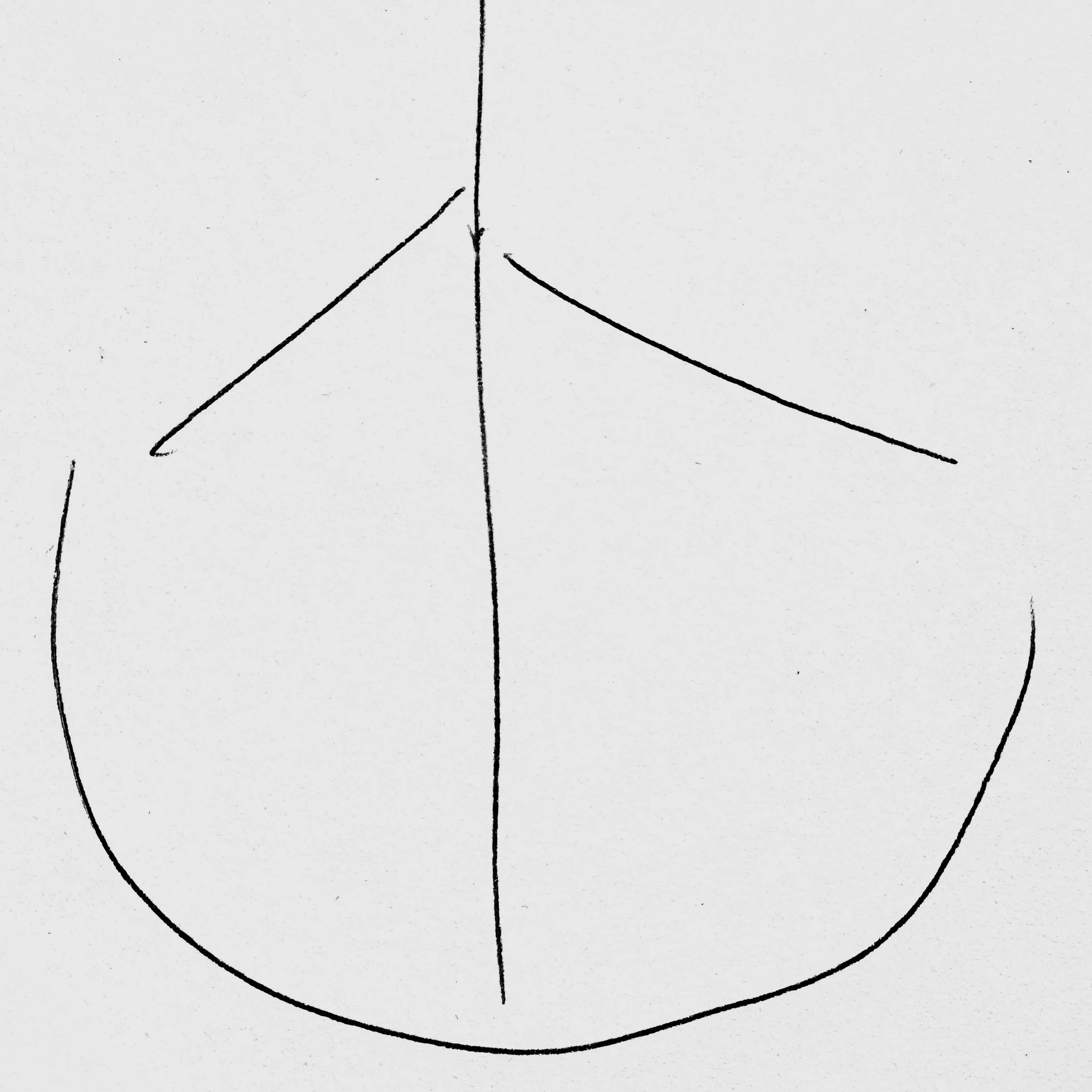

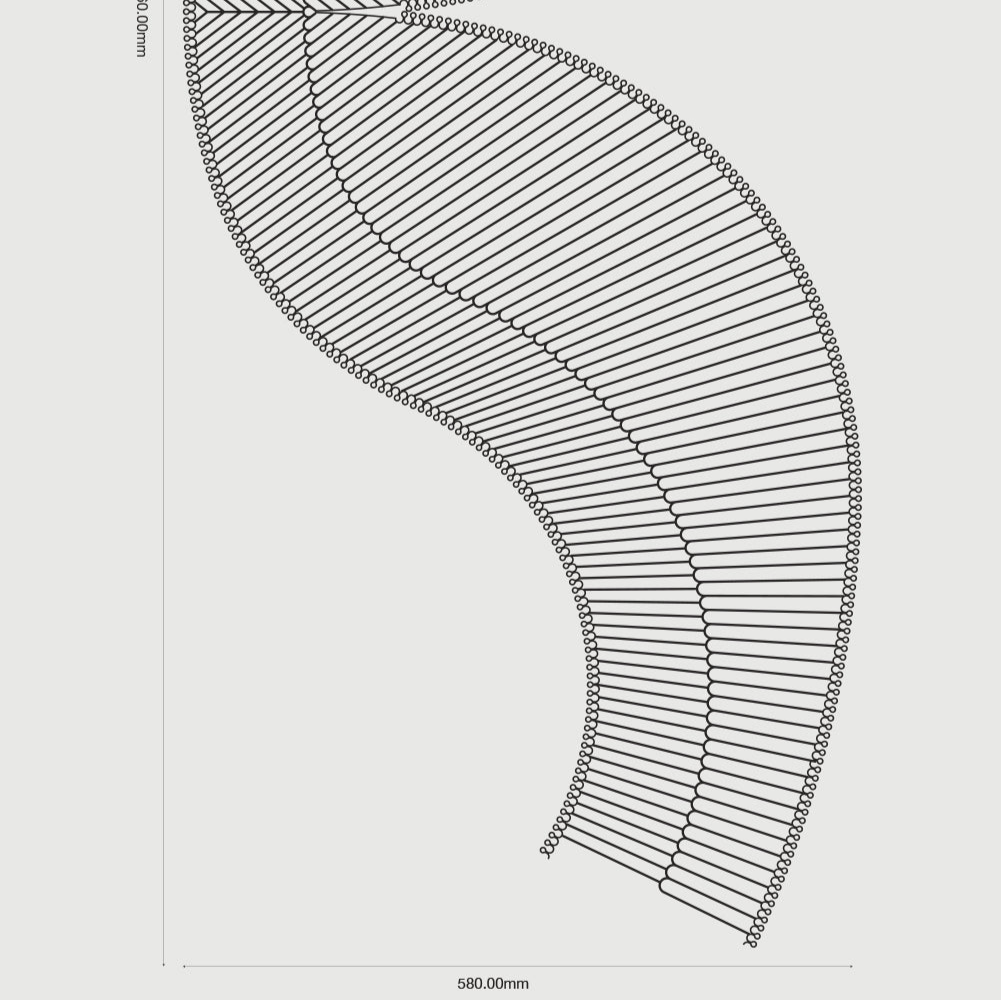

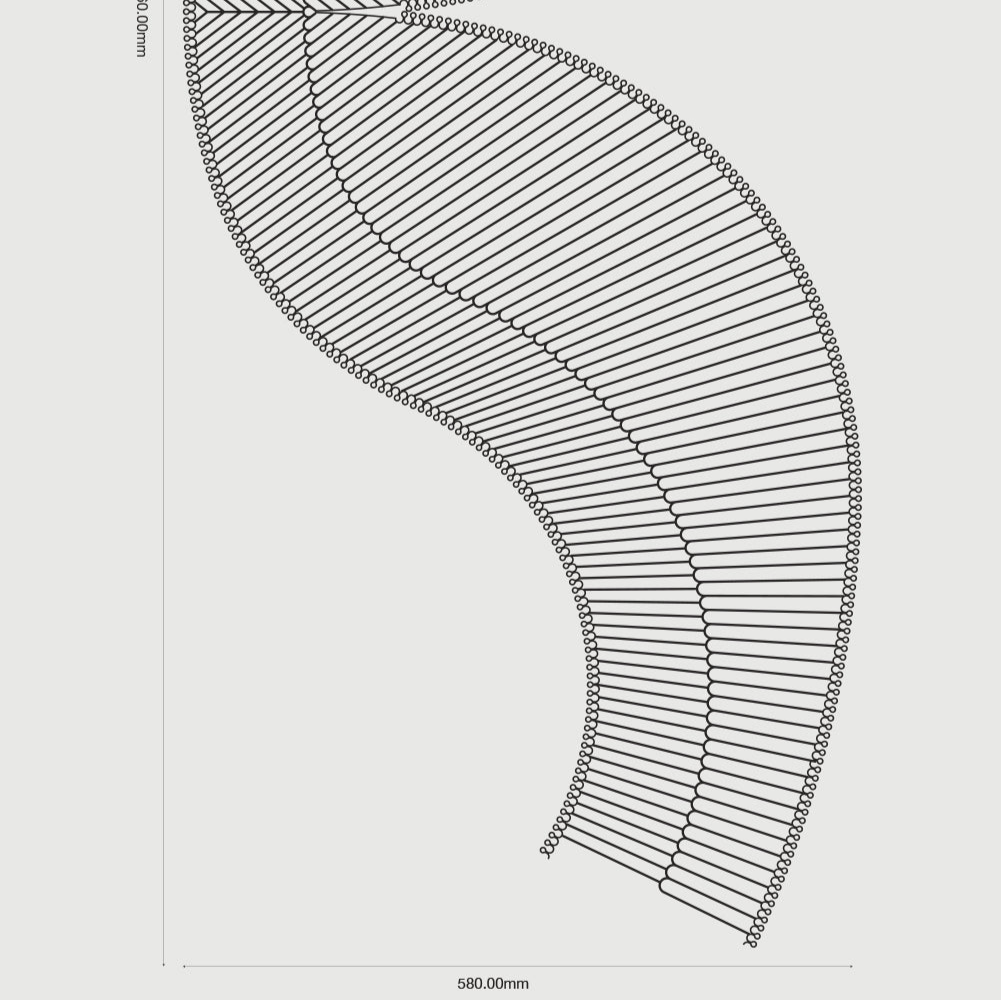

Our lighting pieces are large in volume but minimal in weight. Taking inspiration from the looping framework of the Victorian era’s imposing greenhouses and precisely-engineered bridges, we have designed the unique meshed surface digitally, drawing the intricate weave in one uninterrupted movement. Using additive technology, filaments are fused together to recreate the fluid lines of the design as a flat, airy surface. This is then manipulated into a voluminous, feather-light three dimensional structure, and stitched together like a piece of tailoring.

large in volume but minimal in weight

The minimal forms of the LightMass^ family are big on impact but light in footprint. The filament used in the production of the lighting pieces is composed of a hard-wearing PLA and biopolymer blend that is bio-based and 100% renewable. The FDM additive making method avoids material wastage entirely during fabrication, while the inventive openwork design minimises the weight and mass of material required. With just the one material used in the making of the pieces, future recycling is made easy.

big on impact but light in footprint

Our flexible, hands-on process and the absence of moulds in the fabrication method mean that LightMass^ fittings are easily adapted to a project’s precise needs. We will work with you closely to design and develop bespoke sizes, patterns, colours and compositions.

Raw-Edges are the creative minds behind LightMass^. The London-based design studio, founded by Yael Mer and Shay Alkalay in 2007, is widely celebrated for its thoughtful, inventive approach to product design.